描述

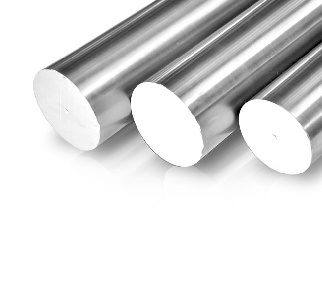

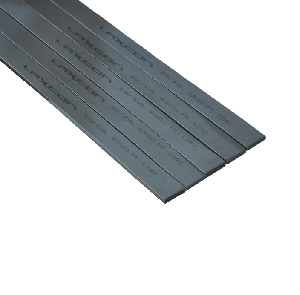

Forged & Proof Machined Bars 锻制精加工棒材

产品描述 / Product Description

中文:

锻制精加工棒材通过锻造工艺和精密机械加工制成,具有优异的机械性能和尺寸精度,适用于高压阀门、航空部件等高强度应用场景。

English:

Forged and proof machined bars are manufactured through forging and precision machining processes, offering exceptional mechanical properties and dimensional accuracy for high-stress applications like pressure valves and aerospace components.

产品规格 / Product Specifications

1. 基本参数 / Basic Parameters

| 标准/Standard | 材质/Material | 直径范围/Diameter | 长度范围/Length | 加工等级/Machining Class |

|---|---|---|---|---|

| ASTM A182 ASTM A479 EN 10250 |

F51/F60, F304/F316 4140, 4340 Alloy 20 |

20mm-500mm | 1m-6m | Class C/Class D |

2. 机械性能 / Mechanical Properties

| 材质/Material | 抗拉强度/Tensile (MPa) | 屈服强度/Yield (MPa) | 延伸率/Elongation (%) | 冲击功/Impact (J) |

|---|---|---|---|---|

| F51 (Duplex) | 750-1000 | ≥550 | ≥25 | ≥100 |

| 4140 | 850-1000 | ≥700 | ≥18 | ≥40 |

| F316L | ≥485 | ≥170 | ≥40 | ≥60 |

3. 尺寸公差 / Dimensional Tolerance

| 直径范围/Diameter | 直径公差/OD Tolerance | 圆度/Roundness | 直线度/Straightness |

|---|---|---|---|

| 20-50mm | ±0.05mm | ≤0.03mm | ≤0.3mm/m |

| 50-150mm | ±0.08mm | ≤0.05mm | ≤0.5mm/m |

4. 表面处理 / Surface Treatment

- 表面粗糙度/Surface Finish: Ra 0.8μm-3.2μm

- 处理方式/Treatment: 精车/Fine Turning | 磨削/Grinding | 抛光/Polishing

- 特殊要求/Special: 钝化/Passivation | 喷丸/Shot Peening

5. 认证与检测 / Certification & Testing

| 检测项目/Test | 标准方法/Method | 证书文件/Certificate |

|---|---|---|

| 化学成分/Chemical | ASTM E1476 | EN 10204 3.1/3.2 |

| 超声波检测/UT | ASTM A388 | 报告/Report |

| 硬度测试/Hardness | ASTM E10/E18 | 随货报告/Test Report |

附加服务 / Additional Services

中文:

– 提供材料追溯报告(MTR)

– 可定制特殊合金成分

– 支持第三方检验(SGS/BV等)

English:

– Material Traceability Reports (MTR)

– Custom alloy compositions

– Third-party inspection available

注:所有数据为典型值,具体参数以实际订单技术协议为准

Note: All data are typical values, exact specifications subject to technical agreement